Dry transfers, also called dry rub transfers or rubdowns, are decals that can be applied to almost any surface, without the use of water or solvents.

Dry transfers are commonly used as a method for applying lettering and graphics to packaging, models, prototypes or any 2D or 3D work.

The use of dry transfer decals is so popular due to the accuracy of colour matching that can be achieved, the range of finishes available and it being a cost-effective alternative to other printing options.

The finish of a dry transfer decal is so detailed that the end result will appear as if the graphic has been printed directly on the surface.

The benefits of dry transfers don’t solely lie with the quality of the finish, the ease in which they can be applied is also hugely beneficial.

Applying a dry transfer is incredibly easy. No cutting or liquid solvent is required - simply press the sheet (on which the decals are printed) to the surface and apply a light pressure in a rubbing motion to the graphics. These will then be transferred to the surface with no fuss.

An added benefit to using dry transfers is their durability - a dry transfer decal won’t loosen or peel off, like a vinyl application would do nor leave any glue or residue. The end result is a high quality, professional finish.

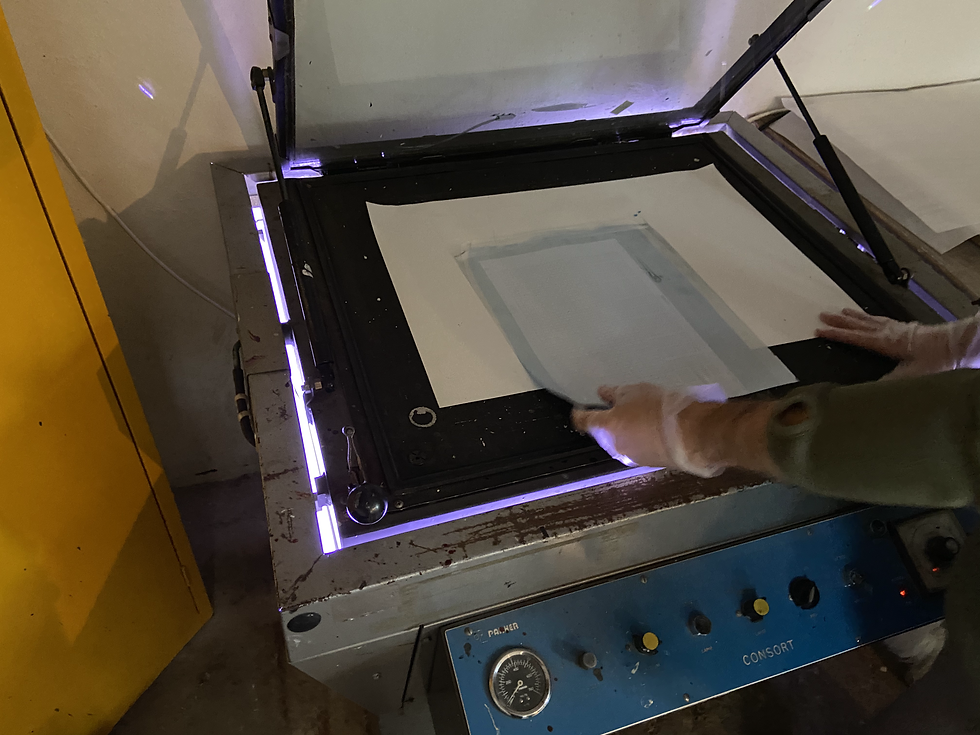

Our dry transfers are made-to-order, using our specialist printing process and are entirely customised to your design.

To talk to us about your project and how we can help, email us at coloursense@btconnect.com

Comments